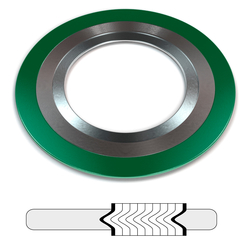

Spiral Wound Gasket

TYPE IHC

DESCRIPTION

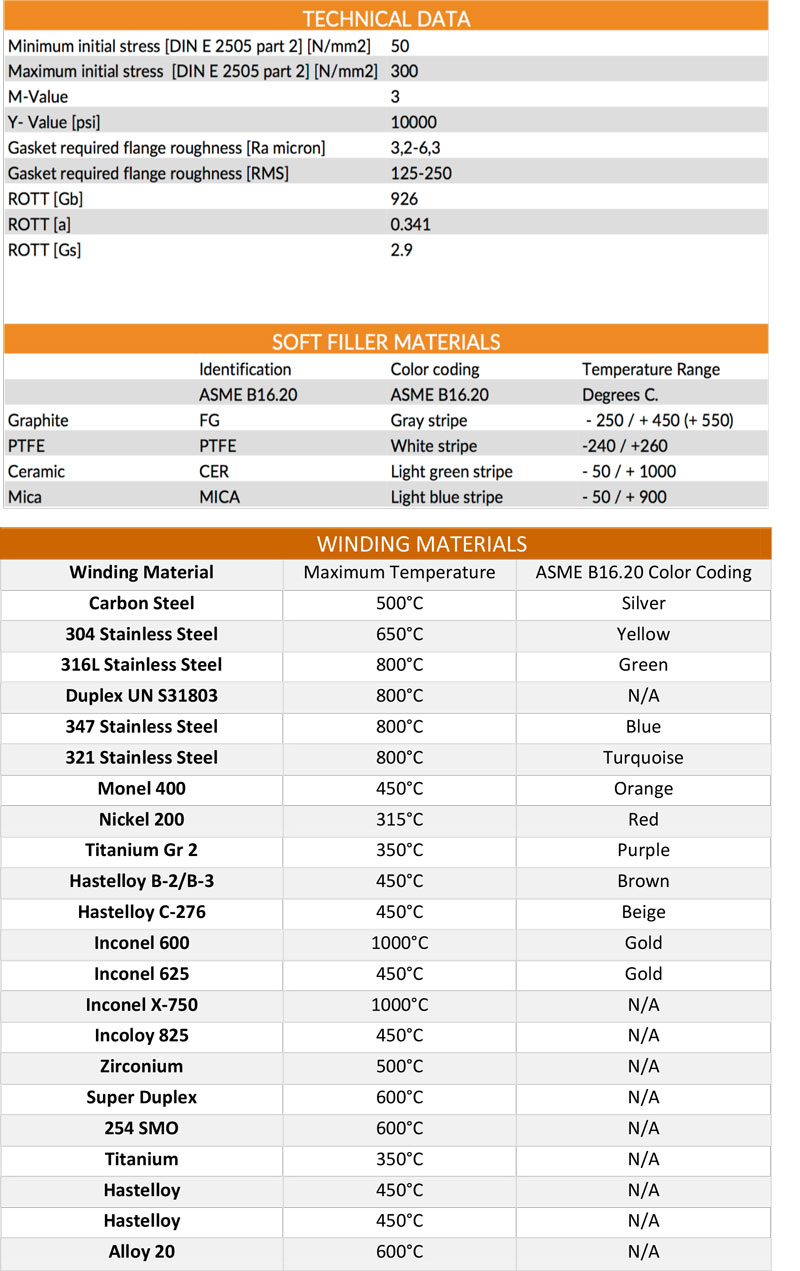

AtraSeal Spiral Wound Gaskets are widely used as high integrity and sustainable gaskets. The sealing element is constructed from preformed, V-shaped metallic windings with intermediate soft sealing fillers. Most used filler materials are Graphite and PTFE. Due to the gasket construction, SWG’s offer high compressibility and recovery. Atraseal type IHC SWG’s are provided with an inner and outer Centering ring. These gaskets are suitable for ASME B16.5 raised faced flanges up to 2500 lbs. and for EN/DIN flanges up to PN400.

APPLICATION

Oil and Gas Industry, Chemical Industry Steam, On- and Offshore exploration, pipeline systems, pressure vessels and exchangers.

CHEMICAL COMPATIBLITY AND TEMPERATURE

Spiral Wound Gaskets can be used in a wide variety of media, i.e. a pH range varying from 0-14. Application/ compatibility guide is available on request. Temperature from

-250 °C up to 450 °C (steam up to 650 °C)

.

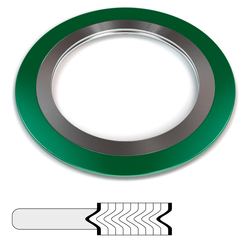

TYPE IH

DESCRIPTION

AtraSeal Spiral Wound Gaskets are widely used as high integrity and sustainable gaskets. The sealing element is constructed from preformed, V-shaped metallic windings with intermediate soft sealing fillers. Most used filler materials are Graphite and PTFE. Due to the gasket construction, SWG’s offer high compressibility and recovery. Atraseal Style IH SWG’s are provided with an inner ring. The IH gaskets are suitable for ASME B16.5 tongue and groove or male / female (Spigot to Recess) flanges up

Available also for Heat Exchanger applications.

APPLICATION

Oil and Gas Industry, Chemical Industry Steam, On- and Offshore exploration, pipeline systems, pressure vessels and exchangers.

CHEMICAL COMPATIBLITY AND TEMPERATURE

Spiral Wound Gaskets can be used in a wide variety of media, i.e. a pH range varying from 0-14. Application/ compatibility guide is available on request. Temperature from

-250 °C up to 450 °C (steam up to 650 °C)

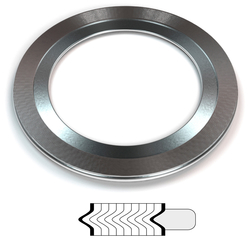

TYPE HC

DESCRIPTION

AtraSeal Spiral Wound Gaskets are widely used as high integrity and sustainable gaskets. The sealing element is constructed from preformed, V-shaped metallic windings with intermediate soft sealing fillers. Most used filler materials are Graphite and PTFE. Due to the gasket construction, SWG’s offer high compressibility and recovery. Atraseal Style HC SWG’s are provided with an outer guide ring. The HC gaskets are suitable for ASME B16.5 raised faced flanges up to 600lbs and for EN/DIN flanges up to PN40. We strongly recommend to use IHC gaskets with inner guide ring in all circumstances.

APPLICATION

Oil and Gas Industry, Chemical Industry Steam, On- and Offshore exploration, pipeline systems, pressure vessels and exchangers.

CHEMICAL COMPATIBLITY AND TEMPERATURE

Spiral Wound Gaskets can be used in a wide variety of media, i.e. a pH range varying from 0-14. Application/ compatibility guide is available on request. Temperature from

-250 °C up to 450 °C (steam up to 650 °C)

.

TYPE H

DESCRIPTION

AtraSeal Spiral Wound Gaskets are widely used as high integrity and sustainable gaskets. The sealing element is constructed from preformed, V-shaped metallic windings with intermediate soft sealing fillers. Most used filler materials are Graphite and PTFE. Due to the gasket construction, SWG’s offer high compressibility and recovery. Atraseal Style H SWG’s are provided with a sealing element only. The H gaskets are suitable for ASME B16.5 tongue and groove or male / female (Spigot to Recess) flanges up to 2500lbs. They are mostly used in pumps and valves.

Available also for Heat Exchanger applications.

APPLICATION

Oil and Gas Industry, Chemical Industry Steam, On- and Offshore exploration, pipeline systems, pressure vessels and exchangers.

CHEMICAL COMPATIBLITY AND TEMPERATURE

Spiral Wound Gaskets can be used in a wide variety of media, i.e. a pH range varying from 0-14. Application/ compatibility guide is available on request. Temperature from

-250 °C up to 450 °C (steam up to 650 °C)

.